Monday, October 29, 2007

Saturday, October 27, 2007

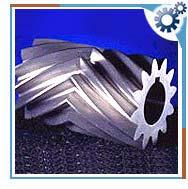

1-Angular Bevel Gears:

These are bevel gears whose shafts are set at an angle other than 90 degrees. They are useful when the direction of a shaft's rotation needs to be changed. Using gears of differing numbers of teeth can change the speed of rotation.

These gears permit minor adjustment of gears during assembly and allow for some displacement due to deflection under operating loads without concentrating the load on the end of the tooth. For reliable performance, Gears must be pinned to shaft with a dowel or taper pin.

The bevel gears find its application in locomotives, marine applications, automobiles, printing presses, cooling towers, power plants, steel plants, defence and also in railway track inspection machine. They are important components on all current rotorcraft drive system.

Thursday, October 25, 2007

2-Bevel Gears

They connect intersecting axes and come in several types. The pitch surface of bevel gears is a cone. They are useful when the direction of a shaft's rotation needs to be changed. Using gears of differing numbers of teeth can change the speed of rotation. They are usually mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well.

These gears permit minor adjustment during assembly and allow for some displacement due to deflection under operating loads without concentrating the load on the end of the tooth. For reliable performance, Gears must be pinned to shaft with a dowel or taper pin. Bevel gear sets consist of two gears of different pitch diameter that yield ratios greater than 1:1.

Types

The teeth on bevel gears can be straight, spiral or bevel. In straight bevel gears teeth have no helix angles. They either have equal size gears with 90 degrees shaft angle or a shaft angle other than 90 degrees. Straight bevel angle can also be with one gear flat with a pitch angle of 90 degrees. In straight when each tooth engages it impacts the corresponding tooth and simply curving the gear teeth can solve the problem. Spiral bevel gears have spiral angles, which gives performance improvements. The contact between the teeth starts at one end of the gear and then spreads across the whole tooth. In both the bevel types of gears the shaft must be perpendicular to each other and must be in the same plane. The hypoid bevel gears can engage with the axes in different planes. This is used in many car differentials. The ring gear of the differential and the input pinion gear are both hypoid. This allows input pinion to be mounted lower than the axis of the ring gear. Hypoid gears are stronger, operate more quietly and can be used for higher reduction ratios. They also have sliding action along the teeth, potentially reducing efficiency.

Applications

A good example of bevel gears is seen as the main mechanism for a hand drill. As the handle of the drill is turned in a vertical direction, the bevel gears change the rotation of the chuck to a horizontal rotation. The bevel gears in a hand drill have the added advantage of increasing the speed of rotation of the chuck and this makes it possible to drill a range of materials. The bevel gears find its application in locomotives, marine applications, automobiles, printing presses, cooling towers, power plants, steel plants, defence and also in railway track inspection machine. They are important components on all current rotorcraft drive system.

Spiral bevel gears are important components on all current rotorcraft drive systems. These components are required to operate at high speeds, high loads, and for an extremely large number of load cycles. In this application, spiral bevel gears are used to redirect the shaft from the horizontal gas turbine engine to the vertical rotor.

Wednesday, October 24, 2007

3-Crown Wheel and Pinion

A crown wheel is a wheel with cogs or teeth set at right angles to its plane and the pinion is a small cogwheel that meshes with the crown wheel. Crown wheel and pinion have excellent heat distortion control, high strength, wear resistance property and noiseless and vibration free operation. They are made of fine-grained steel billet.

The pinion thread is specially made on the thread grinder to ensure proper fitting. Tooth contact of a crown pinion is inspected on a Gleason machine at regular intervals of time for uniform hardness and adequate case depth. They are checked thoroughly for high spots because this ensures premature failure and noise-free operation. The crown wheel & pinion are paired and checked for centralized tooth bearing and desired proximity. An elliptoid contact pattern is ensured between the crown wheel and pinion.

In a machine, when any torque is applied to the drive unit, the tendency is for the crown wheel and pinion to be forced into or out of mesh by the sliding contact. The amount of pre-load on the bearings determines how much torque can be transmitted without allowing end float, which cause the meshing of the gears to become incorrect.

Application

Crown wheel & pinion are used widely in automotive industries. They are one of the most stress prone parts of a vehicle. They are used in automobiles to maintain forward motion. To maintain forward motion both output drive shaft sides covers are removed and the pinion and crown wheel are swapped completely with differential.

Monday, October 22, 2007

4-Crown Wheel

A crown wheel is a wheel with cogs or teeth set at right angles to its plane. The internal diameter of a crown wheel is ground by holding the component in pitch like chucks to ensure accuracy of the finished gear.

As a result of the development of "flat" crown wheels it has become possible to construct a special gearbox. IHC has used these new gearwheels to produce a prototype of a continuously variable speed gearbox.

Applications

Crown wheels are used in motorcycle automotive gearboxes. It is also used in mechanical clocks. The clock consists of a crown wheel, rotated by a falling weight, whose teeth drive the pallets of a verge backward and forward. This verge is connected to an arm with a hammer on the end that struck the bell.

5-Differential Gears

Differential gears link two shafts with a covering, forcing the total of the rotational angles of the shafts to be the same as the rotational angles of the covering. Arrangement of the system is done in such a way that one axle turns faster than the other.

When a differential gear is meshed with the other gear then the highly efficient torque is applied from the differential side gears to the axle shaft. When torque level decreases then the gear separating forces also decreases allowing the axle shaft to rotate independently. Differential gears can add or subtract the movement of two inputs. In practical terms, they will turn the number of revolutions proportional to the movements of both inputs. They are used to convert the lengthwise flow of power from the engine through the clutches, transmissions, and propeller shafts into a right-angle direction. This change allows the engine power to turn the wheels.

In the differential gears there are two coaxial gears, the pinions and the turntable. Pinions are mounted on intermediate shafts and these shafts are connected to a fixed carrier called the turntable. The differential gears are lubricated with a fluid that absorbs heat and increases the life and performance of the gears as well as the wheel. Regular driving subjects the fluid to high heat that breaks the fluid at a later stage. This results in the contact of two metals, which eventually increases the heat and prevents the gear from turning the car's wheel. So, the fluid should be properly checked in regular intervals.

Types of Differential Gears:

There are two designs of differential gears, hypoid and spiral.

a)Spiral Differential:In spiral differential the pinion gears contacts the ring gears at its centerline.

b)Hypoid Gear: In the hypoid the pinion gear contacts the ring gear below the centerline. The size of pinion gear in hypoid differential is much smaller and the contact ratio is high, comparatively hypoid differential is much stronger than the spiral differential.

Applications

Differential gears in automobiles are the most common application of these gears. When the car is moving in a straight line, there is no movement of the differential gear with respect to its axis but when the car takes a turn then these gears help two wheels of the car to rotate differentially with respect to each other. When one wheel is stationary then the counterpart wheel rotates at twice of its expected speed.

Saturday, October 20, 2007

6-External Gear

These are the most often used and the simplest gear system with cylindrical gears with straight teeth parallel to the axis. They are used for transmitting rotary motion between parallel shafts. When a smaller gear called the pinion, drives the larger gear called the wheel, also having external teeth, the corresponding driving and driven shafts rotate in opposite direction. The two gear surfaces come into contact once and so they are noisy at high speed.

External gears are generated with a tool moving forward towards the component axis. Internal gear cutter with very small diameter and few teeth is used for the production of external gear. External gears are widely used in various industrial sectors like coal industry, mining, steel plant, paper industry, and many more.

7-Fine Pitch Gears

They are widely used in aerospace, nuclear and medical industries. They are available in plastic, steel, stainless steel and brass. They are used largely to transmit motion rather than power. They have high tooth strength.

Fine pitch gears are inspected by functional testing on a variable-center-distance fixture. They do not lend themselves to the kind of detailed tooth measurements because of their small dimensions.

Fine pitch gear is used widely in oil industry and for automotive transmission.

Friday, October 19, 2007

8-Girth Gears

The girth gear has been preferred over the gearless drives due to their lower initial cost, simplicity to install, operate and maintain. In the past many years girth gears have gone through enormous improvements. They have high efficiency and the overall life of these gears depends upon proper lubrication and alignment. They are high quality, high precision component. The capital cost of girth gears is lower than others and they take less time to install. They are physically big and due to this they are unable to store for longer periods of time.

Girth gear materials have made several changes on their own. Casting is enhanced using full ring risering techniques. Simulation programs are installed for verification of proper solidification. New materials are used with an added advantage of increase in hardness and therefore increased ratings.

The girth gear is the heart of most mills and kiln drive system. They can't be used in spare parts inventory. They are also used in steel industry, sugar industry, paper and pulp industry

Wednesday, October 17, 2007

9-Hardened and Ground Gears

Hardened and ground gear has two types of shaft arrangements. They can be parallel shaft type or hollow shaft type. Hardened and ground gear delivers a maximum hob rotation and table rotation with excellent machining accuracy. Hardened ground gear provide a noise free and long term operation. They are characterized by high output, easy operation and precise machining. They offer rigidity, strength and high resistance to shock load. They are available in a wide range of sizes and gear ratios.Hardened gears are used in several essential machine tools like wheels, bedways, etc. and are widely used in the aerospace industry.

Hardened and ground gear has two types of shaft arrangements. They can be parallel shaft type or hollow shaft type. Hardened and ground gear delivers a maximum hob rotation and table rotation with excellent machining accuracy. Hardened ground gear provide a noise free and long term operation. They are characterized by high output, easy operation and precise machining. They offer rigidity, strength and high resistance to shock load. They are available in a wide range of sizes and gear ratios.Hardened gears are used in several essential machine tools like wheels, bedways, etc. and are widely used in the aerospace industry.Sunday, October 14, 2007

10-Helical Bevel Gears

Helical bevel gear is a toothed gear in angular design. The input side is provided with a motor flange or a free input shaft and the output side are provided with a free shaft end or a hollow shaft. Helical bevel gears are fitted with flanges of various sizes. Reciprocating tools cuts them. The advantages of helical bevel gears are high efficiency and low reduction rate. The use of helical bevel gear saves energy and cost. Helical bevel gears are manufactured by an alloyed case hardening steel. The gear material is given an extremely strong, homogeneous structure. They can replace worm gears in a variety of applications, particularly in modular machinery. They are also used as storage and retrieval unit. They are commonly used in modern differentials.

Friday, October 12, 2007

11-Helical Gears

Helical gears connect parallel shifts but the involute teeth are cut at an angle to the axis of rotation. Two mating helical gears must have equal helix angle but opposite hand. They run smoother and more quietly. They have higher load capacity, are more expensive to manufacture and create axial thrust.

Helical gears can be used to mesh two shafts that are not parallel and can also be used in a crossed gear mesh connecting two perpendicular shafts. They have longer and strong teeth. They can carry heavy load because of the greater surface contact with the teeth. The efficiency is also reduced because of longer surface contact. The gearing is quieter with less vibration.

Gear Configuration

They can be manufactured in both right-handed and left-handed configurations with a helix angle to transmit motion and power between non-intersecting shafts that are parallel or at 90 degrees to each other. For shaft at 90 degrees, the same helix angles are used and the tooth contact area of the gear is very small. If the angle of gear teeth is correct, they can be mounted on perpendicular shaft by adjusting the rotating angle by 90 degrees. The inclination of the teeth generates an axial force. As the angle of inclination increases the axial force also increases. Thrust bearings can counter these forces.

Applications

These are highly used in transmission because they are quieter even at higher speed and are durable. The other possible applications of helical gears are in textile industry, blowers, feeders, rubber and plastic industry, sand mullers, screen, sugar industry, rolling mills, food industry, elevators, conveyors, cutters, clay working machinery, compressors, cane knives and in oil industry.

Disadvantage

A disadvantage of helical gear is the resultant thrust along the axis of the gear, which needs to be accomodated by appropriate thrust bearings. This can be overcome by the use of double helical gears by having teeth with a 'v' shape.

Monday, October 8, 2007

12-Herringbone Gears

They conduct power and motion between non-intersecting, parallel axis that may or may not have center groove with each group making two opposite helices. The two helix angle come together in the center of the gear face to form a 'V'. in these gears the end thrust forces cancel themselves out. Its difficult to cut this type of gear but its made easier by machining a groove in the face at the point of the apex of the 'V' creating a break in the middle of the herringbone gear teeth. They do not have any separating groove between the mirrored halves.

They conduct power and motion between non-intersecting, parallel axis that may or may not have center groove with each group making two opposite helices. The two helix angle come together in the center of the gear face to form a 'V'. in these gears the end thrust forces cancel themselves out. Its difficult to cut this type of gear but its made easier by machining a groove in the face at the point of the apex of the 'V' creating a break in the middle of the herringbone gear teeth. They do not have any separating groove between the mirrored halves. Action is equal in force and friction on both gears and all bearings. Herringbone gear also allow for the use of larger diameter shaft for the same volumetric displacement and higher differential pressure capability.

The most common application is in power transmission. They utilize curved teeth for efficient, high capacity power transmission. This offers reduced pulsation due to which they are highly used for extrusion and polymerization. Herringbone gears are mostly used on heavy machinery.

Sunday, October 7, 2007

13-Master Gear

They offer high precision, low volume productions. They are used for composite testing of production components. They have high speed, quiet operation, longer life and greater efficiency.

They offer high precision, low volume productions. They are used for composite testing of production components. They have high speed, quiet operation, longer life and greater efficiency.The most common applications are as setting masters and rolling masters for inspection and production applications. They are used to determine the accuracy of work gears. When master gears and work gears are rolled together on rolling fixtures dimensional variations are determined by various indicators, charts or other indicating devices. Master Gears are also used in aerospace and automotive industry.

Friday, October 5, 2007

14-Mill Header

Mill headers find heavy usage in industrial sectors as an essential part of various vehicles and machines. They are used in various industrial sectors including coal and mining, oil exploration, paper mining, chemical industries, cement plant industry, sugar mill and many more. In industrial sectors these gears are used as an important part of conveyors, cranes, elevators, separators and kilns because they offer high power-density and modularity.

Thursday, October 4, 2007

15-Non-Involute Gears

Non-involute gears have reduced specific sliding. Reduced gear sliding has an affect on low speed meshes, where sliding losses predominate. The efficiency of these gears is also increased by the use of less viscous oil.

The tooth profile geometry is uniquely defined by the arc shaped path of contact. The gears manufactured by the same rack cutter have the concave convex mesh. The result of enlarged reduced radius of curvature has as a consequence reduced pressure and better lubrication conditions. The geometry of non-involute gear tooth provides substantially higher capacity than any other gearing.

The disadvantages of the non-involute gearing are lower transverse contact ratio and great sensitivity to the center distance accuracy.

Monday, October 1, 2007

16-Pinion Gears

It is a small cogwheel. The teeth fit into a larger gear wheel. Rotational motion is converted into linear motion when the pinion turns and moves the rack. Pinion gears are engineered to be the best gears.

Pinion gear system involves the use of a small round gear called pinion and a large flat gear called rack, more the number of teeth in the pinion gear, more is the speed of rotation. Pinion with smaller number of teeth produces more torque. Pinion is attached to the motor shaft with glue. Rotation of pinion is done by rotation of pinion about a fixed center that helps the rack to move in the straight line. If the rack is moved and the pinion rotates then the center of the pinion moves taking along the pinion with it.

Subscribe to:

Posts (Atom)